Fast, Accurate and Smooth – Read What’s the Superior 3D Printing Technology

3D Printing Technologies has a significant influence on manufacturing parts. There are lots of options available in the market for customer’s specific needs, some option would work best for you, but some could be worst; The following guide will help you identify the most suitable 3D printing technology to print high-quality 3D parts.

This guide focuses on SLA and DLP technologies. Often newcomers debate on whether DLP or SLA is preferred technology for final 3D printer performance. There are significant differences in the technological approach of DLP (Digital Light Processing) and SLA (Stereolithography).

If you are looking for a 3D printer that delivers high-quality parts with a smooth surface finish, and also want to save time and money. Then you need to read this detailed guide on what is the better 3D printing technology DLP or SLA. Also learn how exactly these technologies work, and also what are its benefits and drawbacks.

SLA vs. DLP – The Simple Analysis

Both the Stereolithography and Digital Light Processing technologies use a vat of liquid resin which then needs a beam of UV light for photopolymerization to 3D print final object from a digital design file; So what makes SLA and DLP technologies different from each other;

The difference is the light source,

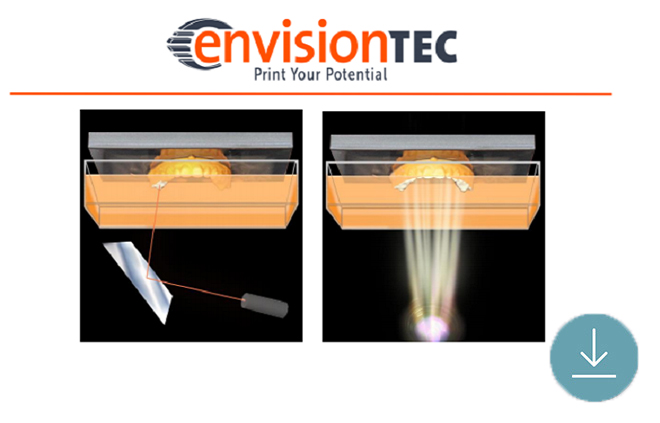

- In SLA, the light gets generated by a laser

- In DLP, the light gets generated by the high-definition projector

SLA and DLP: A side by side comparison of the pros and cons

In SLA, the laser beam draws — lithography, means “to write” — the part image onto the vat of resin, and draws in the interior, albeit not always in that order, curing the liquid, literally, line by line and layer by layer into a final part.

No matter how fast the printer goes, SLA is a time-consuming strategy. Just imagine drawing each layer individually on a sheet of paper with a fine-point pen, outlining the shape, and then coloring in the dense middle sections perfectly with that same pen, page after page. While it may take more time, in the end, the process, theoretically, delivers a more tightly cured product with a finer edge.

In generic DLP, meanwhile, a high-definition projector flashes each complete layer onto the polymer, a process more akin to taking an ink stamp to each page. But because a projector delivers light in pixels — creating volumetric pixels, or voxels, in the resin — there’s an undeniable square, a pixelated shape that inhibits smooth edges.

It is a quick analysis of SLA versus DLP. But is it the whole story? Not nearly — especially if you dig into the multitude of patents filed globally for these processes.

To learn more about these technologies — including Quality, Speed and Accuracy — we recommend you to Download the E-Book by filling the form below;