MARKFORGED X7

Carbon Fiber 3D Printer – Advance Industrial Composite 3D Printer

The Markforged X7 offers users the ability to print not only with Onyx and the full range of Composites ranging from Fiberglass, HSHT fiberglass (high-strength, high-temp fiberglass), carbon fiber, and Kevlar. In addition, it is able to print other thermoplastic materials such as White Nylon, Onyx Flame Retardant Material (Onyx FR) and Onyx Electric Discharge (Onyx ESD). For a business that requires multiple types of printing materials, Markforged’s X7 is the ideal 3D printer. As a 3D printer capable of printing with many diverse combinations of materials, the X7 is the flagship of the Industrial Series.

Carbon Fiber Strength

The X7 3D prints Continuous Carbon Fiber reinforced parts in hours that are as strong as — and capable of replacing — machined aluminium.

ADVANCED SOFTWARE

Eiger is the world’s most advanced 3D printing software. Designed to make manufacturing simpler, Eiger enables you to print plastic, metal, and composite parts straight from your browser and easily control your fleet of 3d printers.

Industrial Reliability and Accuracy

Precision-machined hardware, advanced sensors, and unique software drive industry leading accuracy and reliability. Only Markforged industrial carbon fiber 3D printers offer micron-level laser scanning for closed-loop calibration, reliably yielding parts with 50 μm repeatability and industry-leading surface finish.

With the largest install base in South East Asia, Chemtron is one of the most established Markforged 3D printers distributor in the region.

For more product information, demonstration, and price inquiries

Fill out the form and we’ll get back to you as soon as possible.

Machine Specifications

Physical Dimensions: 584 mm x 483 mm x 914 mm x 48 kg / 106 lbs

BUILD VOLUME: 330 mm x 270 mm x 200 mm

Z Printing Process: Continuous Fiber Reinforcement (CFR)

Z LAYER RESOLUTION: 50 μm – 250 μm

Z Printing Media: Composite Base Filaments, Continuous Fibers

INTERNAL PART GEOMETRY: Closed Cell Infill with Continuous Fiber Reinforcement

Print Bed: Precision Ground Composite

- Onyx™

- Onyx FR™

- Onyx ESD™

- Smooth TPU 95A

- Nylon

- Precise PLA

- Fiberglass

- Carbon Fiber

- Carbon Fiber FR

- Aramid Fiber (Kevlar®)

- HSHT Fiberglass

- Fiberglass

About the X7

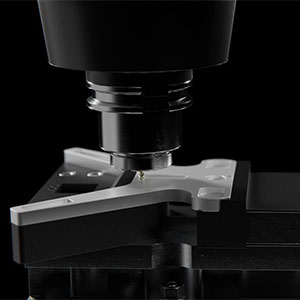

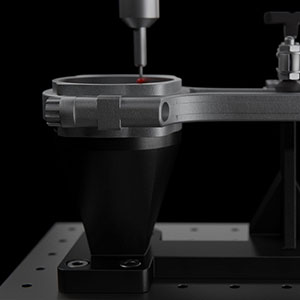

The Markforged X7 CFR industrial carbon fiber 3D printer is designed to deliver consistently accurate parts through precision-engineered hardware, advanced sensors, and cutting-edge software. It features a reinforced, precision-machined gantry and a removable, precision-ground print bed with 10 μm repeatability. The filament extrusion system, from nozzles to extruder hobs, is built to withstand wear from micro carbon fiber-filled nylon filaments, ensuring high-quality prints over thousands of hours. Out-of-material sensors keep the printer running continuously, while a scanning laser on the printhead dynamically adjusts the first layers for optimal bed adhesion and inspects printed parts for accuracy.

Equipped with a 3rd-generation fiber reinforcement system, the X7 allows for the incorporation of continuous fiber into parts. Markforged composite printers uniquely support the production of four types of continuous fiber-reinforced components.

Applications

Create various industrial tools at faster rate with amazing cost savings

End Effectors

Typical Machined Cost – $285.61Markforged 3D Printed Cost – $9.45Savings – 97%

Soft Jaws

Typical Machined Cost – $ 721.70

Markforged 3D Printed Cost – $ 116.04

Savings – 84%

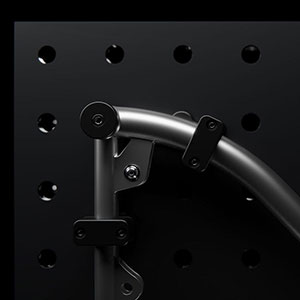

Welding Fixtures

Typical Machined Cost – $ 1050.82Markforged 3D Printed Cost – $ 85.92Savings – 91%

CMM Fixtures

Typical Machined Cost – $ 662.10Markforged 3D Printed Cost – $ 36.03Savings – 95%

Assembly Jig

Typical Machined Cost – $ 436.50Markforged 3D Printed Cost – $ 8.22Savings – 98%

Interested in learning more about Markforged industrial 3D Printers?

Fill out this form and we’ll give you an overview of 3D printing technology, discuss potential applications, and help you determine where 3D printing fits in your business.